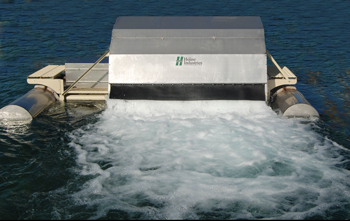

ECS House Industries, Inc. is the leading manufacturer of floating brush aeration equipment in the United States and abroad. The floating brush aerator offers many advantages versus other types of surface aeration equipment.

First, it enhances oxygen transfer rates by “sheering” the water and creating large quantities of fine bubbles for better oxygen transfer. An abundance of bubbles created in this process are the key to enhanced oxygen transfer efficiency, commonly referred to as the Standard Aeration Efficiency (SAE). The more fine bubbles created, the more the overall surface area is increased, which allows the bubbles to capture the oxygen in the air and dissolve this oxygen into the wastewater. ECS House Industries’ unique blade and “tip” design, along with the rotor speed, provides the best oxygen transfer among other floating brush aerators.

The mixing profile of the floating brush aerator moves the wastewater in a horizontal pattern, which prevents short-circuiting from occurring in lagoon applications. This type of horizontal mixing enhances lagoon applications that utilize an anaerobic sludge digestion process. The horizontal mixing circulates highly oxygenated water over the top few feet of a lagoon, significantly reducing the BOD and creating an oxygen cap across the lagoon to reduce odors.

The ECS House floating brush aerator can be used for partial mix and/or complete mix lagoon applications. In addition to these applications, our floating brush aerators can be used in SBRs, equalization basins, aerobic digesters and oxidation ditches as well as in any circular, square or rectangular shaped basin that needs aeration.

DID YOU KNOW?

THE FLOATING BRUSH AERATOR SYSTEM CAN DECREASE YOUR ELECTRICITY COSTS. IN THE CASE OF BELL CARTER, USING THIS TYPE OF AERATION SAVED THEM $323,000 OF ELECTRICITY COST OR 2.7M kWH/y OF ENERGY.

View Bell Carter Case Study

Overview

The floating brush aerator provides effective and efficient wastewater treatment through superior oxygen transfer and mixing rates, leading to increased performance using less horsepower. Additionally, our pumping rates range from 3,000 gpm/hp to 3,800 gpm/hp depending on the aerator size and model. These high pumping rates lead to efficient mixing profiles in multiple wastewater applications.

Other ways in which this rotor saves you time and money include:

- Variable frequency drive and/or dissolved oxygen sensor result in energy savings.

- High oxygen transfer and mixing rates reduce horsepower requirements; energy savings can range from 30 to 75%.

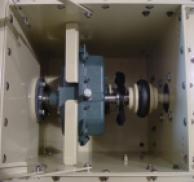

- Grease lubricated tail-bearing with an L10 (subscript) rating of over 100,000 hours and zero dependence on plastic, wastewater lubricated bearings.

- Zero belt maintenance with direct drive models.